Our Line of Top Quality Vacuum Equipment

Combo Vac

Features

15 m3 Complies with TC407/412 CSA B620

– Current Edition

- 15 cube capacity

- 11m3 debris 4m3 water

- Full open hydraulic rear door

- 6″ + 4″ heated and code compliant rear valves

- Hydraulic vibrator

- Robuschi RB-DV-85 blower, 1600 CFM

- 27″ HG max vacuum

Wash System

- Wash system c/w Cat 660 triplex plunger pump

- Hotshot 120 volt heater, 980,000 BTU/hr

- Hydraulic hose reels

- All enclosed inside a heated, insulated aluminum enclosure

Specs & Configurations

Standard Configuration

Design:

Tank Construction, tank design and associated equipment are compliant with Transport Canada TC407/412 CSA B620 current edition and ASME section VIII Division 1, of the ABSA Boiler and Pressure Vessel Code.

Debris / Water Components

Debris Tank 11 Cubes (2420 Imp Gal +3% Outage):

- 78″ Diameter

- Pressure vessel hydrotested to 40 PSI

- Global hydraulic vibrator

- 3 stage double acting hydraulic hoist cylinder

- Full opening hydraulic lift rear door c/w locking style top hinge and 6 pin wheel door locks

- Two recessed liquid level indicators D/S and P/S c/w indicator with grab handle

- 3″ x 30 PSI pressure relief vent

- Rear door top lock assembly and tank safety post

- Operating Temperature -20 degrees F to 200 degrees F

- 8″ Primary internal shutoff SS float ball and rubber seat assembly with 6″ flanged outlet

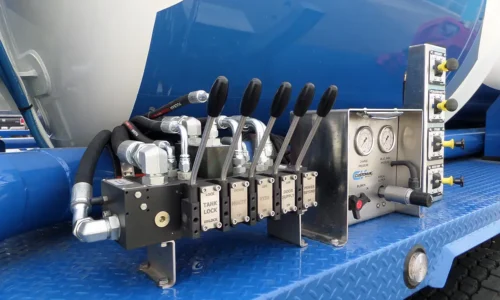

- 6″ heated isolation valve with air control switch at operation

Water Compartment 4 Cubes (880 Imp Gal ):

- 20″ Manway

- Recessed liquid level indicators on P/S c/w indicator with grab handle

- 2″ Heated Breather, fill and suction c/w Riser/Vent Pipe

- 2″ Heated Drain Valve c/w air actuated valve. Switch control at operator station

- 2″ Heated hard piped supply line, c/w composite loop hose and valve. Direct connection through wash cabinet to wash pump

- 2″ Vacuum Changeover Valve & Air Control switch at Operator Station

- Catwalk, back rail and ladder D/S

Product Valves

- 4” Betts load valve c/w 6″ sandpipe and aluminum camlock/cap D/S

- 4″ Betts load valve c/w aluminum camlock/cap P/S

- 6” Betts discharge valve c/w aluminum cap (Center) All rear valves heated, air and equipped with flip style valve controls

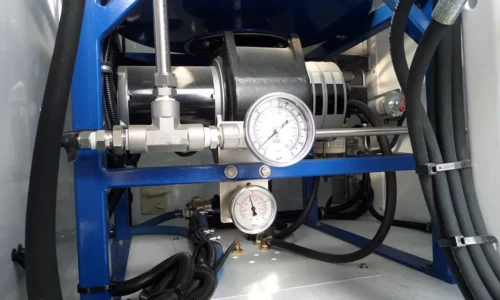

Blower & Associated Components

- Robuschi RB-DV 85 High Efficiency Tri-Lobe Design

- 27” Hg Maximum Vacuum (1600 CFM)

- Oil Free Operation (Except Sealed Reservoirs)

- 6″ Four-Way Divertor Valve (Vacuum to Pressure Modes)

- 6″ Double Door Check Valve (To Prevent Blower Back Spin)

- Pre-stage housing c/w 16″ Dia. x 20 Micron Rating (Washable) Blower Filter

- High Torque/High Temp Blower Drive Coupling with Flexible Insert

- One Exhaust Silencer, One Intake Silence

- High temperature blower alarm c/w gauge

- Diesel flush ball valve assembly

***Note*** An upgraded Hibon 822XL blower (2780CFM) is available on this design

Wash System

Wash Cabinet:

- Custom Vac “in house” manufactured Aluminum 40″ Crossover cabinet (standard), heated and insulated with excellent interior and exterior lighting

- Small door in large door for hose access P/S

***NOTE*** These cabinets are also available in a 60” design

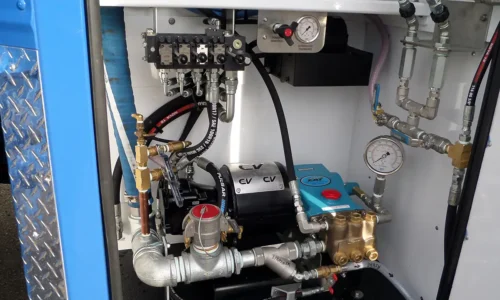

Standard Wash System (Access on Passenger Side):

- Cat 660 Pressure pump (Rated 10 GPM @ 3000 PSI Max)

- 1-1/4”″ Stainless Steel strainer,

- Three Hydraulic Hose Reels (100′ x 3/8″ pressure hose, 100′ x 3/8″ temperature rated steam hose and a 100′ x 3/8″ degreaser hose).

- Pressure trigger guns, wand, nozzle and quick coupler

- Stainless Steel glycol and soap tanks

- Steam wand, nozzle and quick coupler

- Degreaser assembly c/w gun, wand and nozzle

***NOTE*** An upgraded Pressure pump is available that would supply 20 gal per minute at up to 4000 PSI

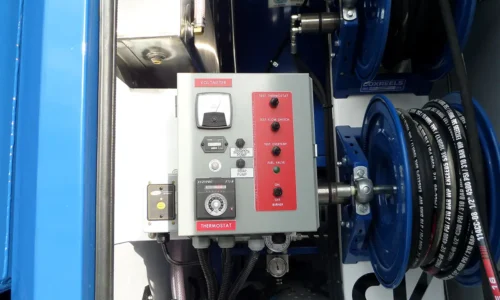

Hot Water System:

- Hot Shot 980,000 BTU/hr Burner c/w Honeywell control, relief valves temperature gauge Wet steam kit, Diagnostic panel

- New Style 18 GPM Solid Brass Flow Switch with no bypass line

- Safety feature: a Maximum 340 deg. Auto Shut-off on heater system

- 3000 Pure Sine inverter to operate the burner assembly

- Custon Vac aluminum vent hood is installed above the insulated stainless steel burner vent stack

- Glycol Flush Tank /Air Blown System

- Hard piped plumbing in Stainless Steel where applicable

Equipment

- Rig to Pull Pup (Standard)

- Dog house

- Hydraulics as required c/w hose and fittings to operate trailer functions

Toolbox

- One 60” W x 12” D x 17”H steel box c/w 2 access doors D/S

- 2 rear skirt fitting boxes

Paint / Coating

- Entire tank and body of vacuum system will be sandblasted, primed and painted up to 2 colors

- Water compartment internally lined

Frame, Decking, Trim

- Full length 1/8” checker plate hose tray/fender assembly with heavy duty outrigger supports & 1-1/4” steel tubing handrails, close in plates

- Ladder and platform P/S

- Code rear bumper (flip up style)

- Slide out style chain hangers

- 4 flip style placards

- Mud flaps c/w anti-sail brackets

- 20 lb. fire extinguisher with mounting bracket and cover

- 50’ ground cable c/w reel